rockwell hardness test machine university of evansville|rockwell hardness test steps : makers The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied . Resultado da 14 de jan. de 2024 · 1. Video Quality. Both MKV and MP4 container formats can provide high-quality video playback. The video quality itself is not determined by the container format but rather by the video codec used to compress the video data. Both formats support a wide range of codecs, .

{plog:ftitle_list}

The latest tweets from @deborapeixoto__

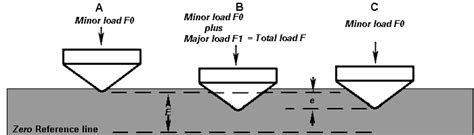

On February 11, 1919, Hugh Rockwell and Stanley Rockwell received a patent for the Rockwell hardness tester, a device for measuring the resistance of .In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the specimen) as well as measurement errors .

Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the .Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the .The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied .The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a .

what is rockwell hardness

Hardness testing is commonly used for material evaluation due to its simplicity and low cost, relative to other assessments of these qualities. Rockwell hardness does have a relationship to tensile strength in some .Learn all you need to know about Rockwell hardness testing – including test definitions, test calculations and insight into Rockwell hardness testing machines and HRC hardness testers – with knowledge and expertise from . The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter .

compression test yamaha outboard

Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a . ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for . Rockwell hardness testing machine. . African University of Science and Technology, Abuja. Date: 03/03/2019 . Citations (3) References (0). Another way to discuss the present data work is to .

rockwell hardness testing advantages

The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine knives. . How Rockwell Hardness Applies to Machine Knives.Find here Rockwell Hardness Tester, Rockwell Hardness Testing Machine manufacturers, suppliers & exporters in India. Get contact details & address of companies manufacturing and supplying Rockwell Hardness Tester, Rockwell Hardness Testing Machine, Digital Rockwell Hardness Tester across India.Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). . An Introduction to Materials .

A full selection of hardness testers, testing machines, testing equipment and accessories for Vickers, Knoop, Brinell and Rockwell hardness testing from Struers, the world’s leading materialographic and metallographic equipment supplier. . Vickers, Knoop, Brinell and Rockwell hardness testing; Load ranges: 200 gf - 250kgf, 200 gf - 750 kgf . The hardness tester developed out of the need for a machine that could quickly and easily measure the effects of heat treatment on the bearing raceway, or track. . The Rockwell hardness test remains the most efficient and widely used hardness test today and is recognized as one of the 20th century’s metallurgical innovations. Learn More .

The Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article. The Rockwell hardness test involves making an indentation on the test material. The indenter is either a conical diamond or a steel ball. Indenter ball diameters range from 1/16 to 1/2 inches and are chosen based on the test parameters.

Our range of Rockwell Hardness Testers test the hardness value of various materials according to Rockwell Principles. . These units measure the depth difference between the primary and testing load and convert the depth difference to the hardness value. Machines can be operated semi-automatically. They are essential testing instruments for .

E-18 Standard Test Method for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Material . Learn More About Hardness Machines. Please Select Your Preferred Region Dismiss Region Selector . Asia Pacific 中国 India 日本 대한민국 台灣 ประเทศไทย CONTACT INFORMATION 825 University Ave Norwood, MA, 02062 .

Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. .

1. AIM: To determine the Rockwell Hardness of a given test specimen II. APPARATUS: Rockwell Hardness testing machine, Test specimen. III. THEORY: HARDNESS- It is defined as the resistance of a metal to plastic deformation against Indentation, scratching, abrasion of cutting. The hardness of a material by this Rockwell hardness test method is . 12. Working Principle 1. SELECTING THE HEAD AND TEST BLOCK Hardened steel and hard alloys like Cast Iron were tested in the Rockwell C scale, using a diamond cone as head and a 150 kg major load. .Rockwell hardness testing machine series Versatile smart models 3 models to suit practically every application Features Specifications External dimensions (512) 434 65 218 352.4 162 150 13 780 (30) 113 214 180 502.5 235 235 502.5 180 214 113 (30) 780 13 150 162 352.4 218 434 65 (512) 212.8 (512) 434 65 218 352.4 162 150 13 780Analog models display the test result through a dial on the front of the machine. They are simple and easy to use and very accurate. . brass, or aluminum that have been specially heat treated and calibrated for consistency. By using a .

compression tester adapter 10mm

Rockwell Hardness Testing Machine - Download as a PDF or view online for free. . University of Gujrat (UOG), Gujrat. 2 3. Group Members 3 Group Members Introduction 13033386-017 13033386-021 13033386-03513033386-018 Group Leader 13033386-024 13033386-047 13033386-050 .The HR-210MR is an economical Rockwell hardness testing machine to suit practically every application you need. The MR indicates the Rockwell testforce range. It offers you the following benefits: The frame was designed with great care to provide maximum clearance for positioning the work piece. All you need is a flat table for mounting these .

Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing

ZHR8150 Rockwell and Superficial Rockwell hardness testing instrument; Building on the long-lasting quality and success of the previous ZHR series, with a brand new touch screen display to make Rockwell hardness testing even easier and more reliable. Like all ZwickRoell Rockwell hardness testers, these instruments support fast, accurate and .The DuraVision universal hardness testers for standard load ranges of 0.3-250 kgf or 3-3,000 kgf can be used for Vickers, Knoop, Brinell, and Rockwell tests, as well as for carbon and plastics testing.All methods are covered by the ISO 6506, ISO 6507, ISO 45452, ASTM E384, ASTM E92, ASTM E10, ISO 6508, ASTM E18, DIN 51917 and ISO 2039 standards. The DuraVision .Metallic materials - Rockwell hardness test - Part 2: Verification and calibration of testing machines and indenters. This document specifies two separate methods of verification of testing machines (direct and indirect) for determining Rockwell hardness in accordance with ISO 6508-1, together with a method for verifying Rockwell hardness .

rockwell hardness testing

The hardness test is performed to determine the suitability of a material for a given application. Rockwell hardness test is developed by the Wilson instrument co U.S in 1920. This test is an indentation test used for smaller specimens and harder material. This hardness test is preferred because it is simple, easy and relatively nondestructive . Fig. 3-17 Schematic Diagram of the Principle and Test Process of Rockwell Hardness Test (a) Add preload (b) Add main load (c) Unload main load. Hardness symbol: Head used: Total test force N: Scope of application . has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools .

In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different indenter types, such as diamond cones and carbide balls. + 86 755 61301520; [email protected]; Search. . or Vicker test which required expensive machines to be .Portable Rockwell hardness testers are available, which allow for on-site or field hardness testing. This is advanta-geous for applications where it is not feasible to transport samples to a laboratory or for situations that require imme-diate hardness assessment. Portable Testing 1.1

compression tester adapter kit

compression tester adapter set

WEB27 de dez. de 2018 · Colored version of my Momo pic. 00:00 00:00 Newgrounds. Login / Sign Up. Movies Games Audio Art Portal Community Your Feed. Fir3Ba11 just joined the crew! . my-hero; my-hero-academia; yaoyorozu; Plenty more like this here! Featured in 18 Lists; You might also enjoy. Licensing Terms.

rockwell hardness test machine university of evansville|rockwell hardness test steps